A collaboration with a textile company has yielded impressive results after fibres from discarded cloth have been successfully recycled into paper products that can be printed on.

Baddeley Brothers has been working with FibreLab to test printing on Papertex, the name being given to an innovation by the East London company.

FibreLab is a hyper-local textile recycling service. It collects textile waste from London businesses of all types – from fashion brands and garment manufacturers to hotels and film productions.

CEO Kaela Katz said: “The need for FibreLab came from my personal frustration with the fashion industry and the immense amounts of waste that businesses generate. So often the blame is put on consumers, but actually, businesses generate significantly more carbon emissions and waste, and they need to be held accountable.

Cutting carbon

“Throughout my master’s research, I interviewed countless London-based fashion businesses and found that the problem was the lack of easily accessible textile recycling solutions. Having a service local to the area means that we can increase transparency—so clients know where their textile waste is actually going and how it is being processed. It also allows us to cut down on the carbon emissions and plethora of other issues that come with exporting waste abroad.”

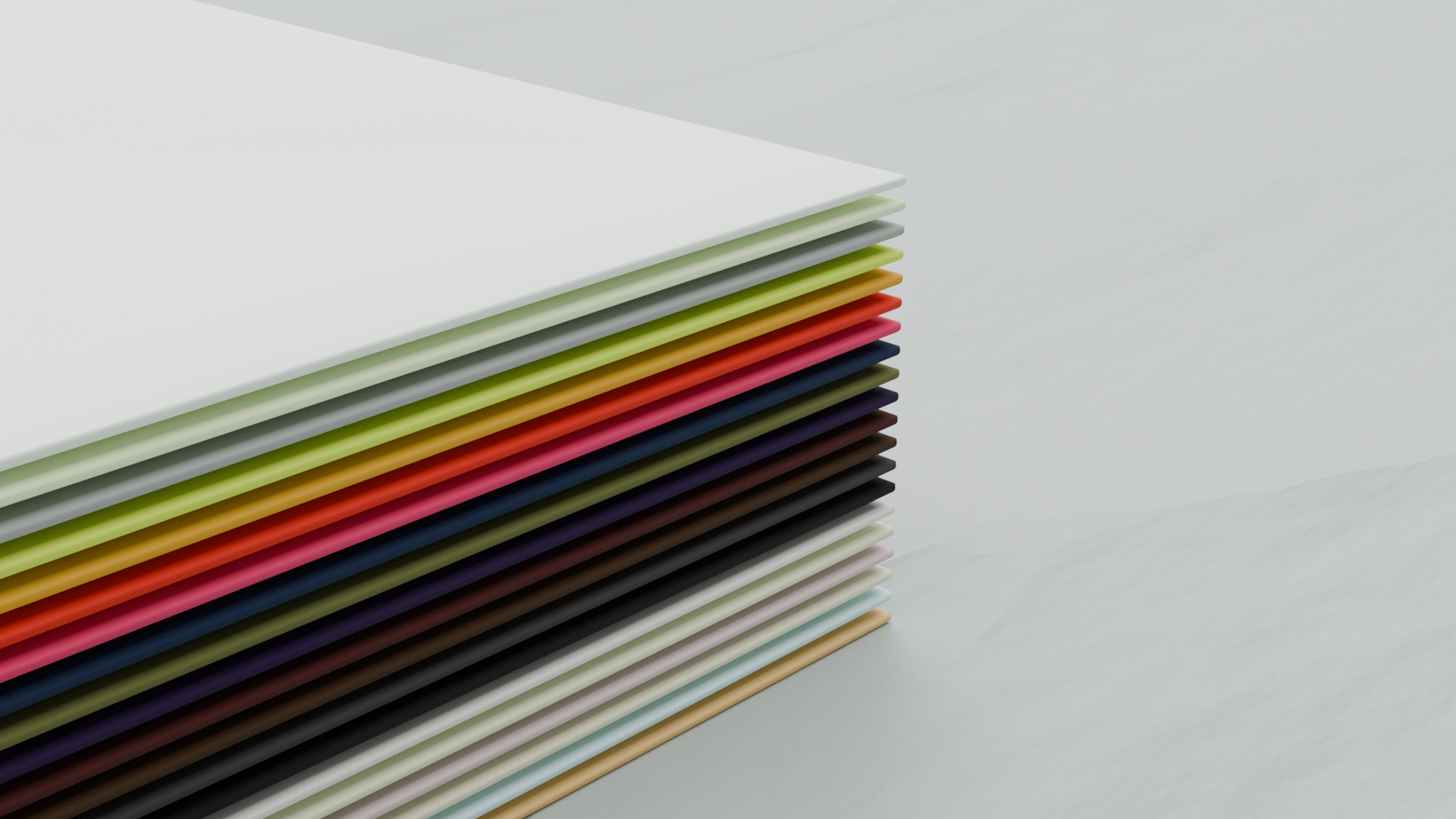

Once the material is collected, it goes back to the studio in East London and the textiles are sorted by fibre type and colour, and put through a custom-built shredder to make raw, recycled fires.

There is then a wide range of products and materials that can be developed, and for Baddeley Brothers, the most interesting and recent innovation is Papertex.

Kaela continued: “The core of our business model is our Textile Shredding and Recycling Service, but as we’ve been developing the business over the last year, we’ve noticed that businesses were interested in seeing a final product output rather than purchasing the recycled fibres.

Making paper from cloth

“Since then, we’ve been working to develop some solutions–about 6 months ago we were very lucky to have received an Innovate UK grant to develop Papertex, a paper material made from 100% recycled textile waste. The papers are a great output for the natural fibres that we receive, like cotton, wool and silk.

“We were sending our recycled fibres to Tom at the Paper Foundation so he could process them into paper for us. Once we developed successful papers, the next challenge was figuring out how to print on them and which processes would work well with the qualities of the recycled papers. Tom referred us to Baddeley Brothers. They helped us test quite a few different printing techniques, and we were thrilled with them.”

Baddeley Brothers commercial director Charles Pertwee said: “Supporting start-ups, especially local ones as we were once 164 years ago! is really important to us. I find the whole idea of repurposing existing materials for second or third use stimulating. It provides us with an advantage in familiarising ourselves with the type of materials we may handle in the future.

“We undertook various proofing exercises. It was exciting to see how the different materials performed. There were surprises using matt and gloss foils, but also how well the material blind embossed and debossed. We learnt a thing or two—matt foil worked better on fluffy, less calendared material, for example.”

Kaela added: “We’ve especially loved the way the deboss effect turned out on the black cotton papers with our logo. Our logo has very fine, detailed lines, so it was very exciting to see it work so well on the papers.

“We try to get the businesses who recycle their textile waste with us to buy back the materials as papers, but the customer base is really wide and spans industries.”

Fibrelab is helping to divert textile waste from reaching landfill or incineration and also cutting down on new raw material usage for products such as paper. The company tracks all the kilos it collects and issues impact reports detailing how much carbon was saved by using its services, converting it into the equivalent of trees planted.

Papertex Black

Papertex green

Papertex black

Papertex detail green

Papertex green

FibreLab Papertex black